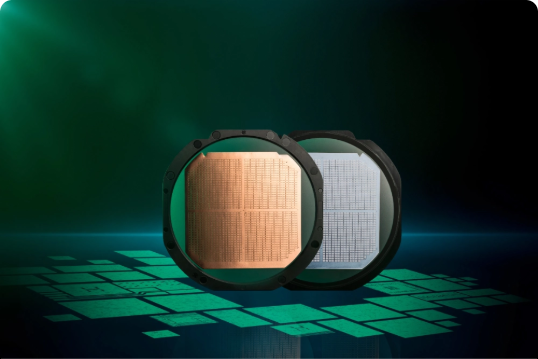

Die Top System - Fully leverage the performance of power modules

Heraeus Electronics Die Top System (DTS) has taken the lifespan and power density of power modules to a new level, which is key to helping customers break free from the constraints of traditional chip connections. The use of DTS can greatly enhance the durability and efficiency of high-power applications.

Main features of Heraeus Electronics Die Top System

The reason why Heraeus Electronics DTS stands out among similar products is that it has made significant progress in reliability and current carrying capacity:

Performance enhancement: Compared to chip bonding and aluminum wire bonding, the current carrying capacity of the chip is increased by more than 50%, and the service life is extended by more than 50 times.

Higher junction temperature: exceeding 200 ° C, thereby reducing power derating and potentially reducing chip size.

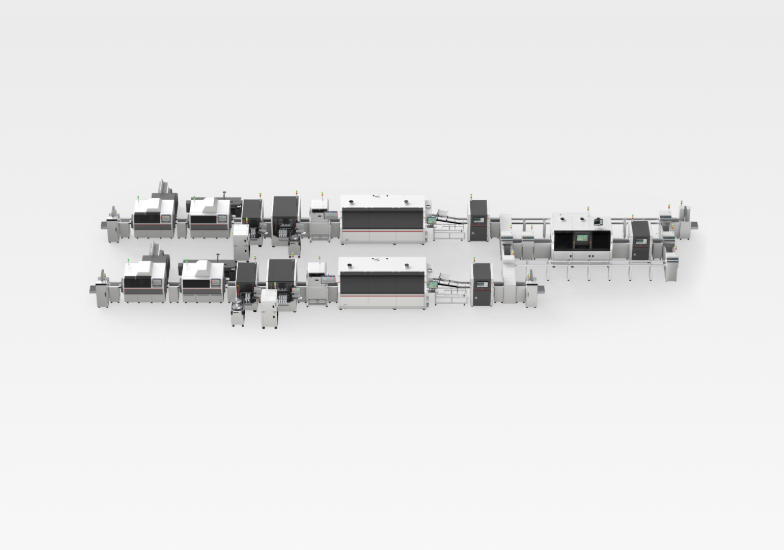

Maximizing cost-effectiveness: significantly reducing labor costs, optimizing performance, and improving profitability.

Advanced technology and customized services

Considering customers' requirements for precision and customization, Heraeus Electronics can customize DTS according to specific needs ® Customizing the configuration brings significant technical advantages:

Selection of bonding substrates: various core materials such as bare copper and copper alloys, as well as functional surfaces such as silver, gold, or palladium. The thickness range is 30-500 µ m, the thermal conductivity is 180-390 W/mK, and the tensile strength is 200-650 N/mm2.

Pre applied sintered silver: To ensure optimal sintering effect, it is recommended to use a pressure range of 10-30MPa and a temperature range of 230-280 ° C. If the thermal conductivity exceeds 150 W/mK, no cleaning process is required.